MAGNiflex is a Europe-wide supplier for market-leading companies in the field of warehouse technology!

Comprehensive support, years of experience, and the manufacture of complex special components have made us a competent partner. We always see new tasks as an opportunity to impress with our capabilities. Find out more about our company and portfolio on the following web pages.

MAGNiflex is a traditional and dynamic company that established its own production facility in Olsztyn (Poland) in December 2002. The combination of the Latin words “magni” (high quality) and “flex” (adaptable) resulted in our company name, which today stands for quality products throughout Europe. In August 2003, we purchased our current headquarters in Rogiedle. Since then, our product range has expanded steadily and now includes post supports for wooden fences, fence posts, ram protection corners, ram protection walls, crossbars made of hot-rolled shaped and angle steels, all accessories for pallet racks, welded parts, welded constructions, industrial railings, and protective grilles for racks and industry. Using state-of-the-art machinery, we transform 5,000 tons of steel into high-quality products every year. Our high level of expertise in sheet metal working and powder coating ensures that our customers enjoy all the benefits of a finished end product from a single source. Our top priority is to produce environmentally friendly, high-quality, and efficient products for our customers.

MAGNiflex continuously invests in technological progress so that it can continue to impress with cost-effective, high-quality solutions in the future!

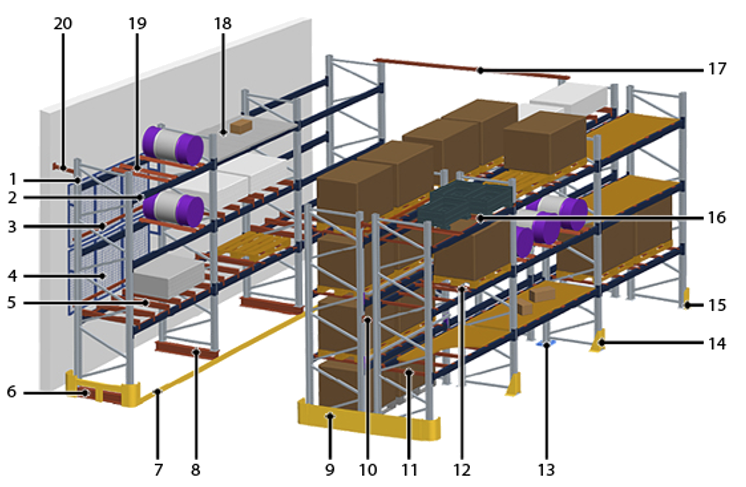

Basic elements for pallet racking systems

| No. | Description | No. | Description |

|---|---|---|---|

| 1 | Frame (fast version) | 11 | Cross support for wooden floors |

| 2 | Longitudinal beam (angle steel) | 12 | Pallet cross support |

| 3 | Anti-slip device for pallets | 13 | Shims |

| 4 | Safety gate | 14 | Collision protection (U-shape) |

| 5 | Increased cross-supports | 15 | Collision protection (L-shape) |

| 6 | Side frame protective device (barrier) | 16 | Container support |

| 7 | Guide rail | 17 | Portal connection |

| 8 | Load distributor | 18 | Metal shelf |

| 9 | Side frame (plank) protective device | 19 | Barrel supports |

| 10 | Frame connector | 20 | Wall connectors |

| No. | Description |

|---|---|

| 1 | Frame (fast version) |

| 2 | Longitudinal beam (angle steel) |

| 3 | Anti-slip device for pallets |

| 4 | Safety gate |

| 5 | Increased cross-supports |

| 6 | Side frame protective device (barrier) |

| 7 | Guide rail |

| 8 | Load distributor |

| 9 | Side frame (plank) protective device |

| 10 | Frame connector |

| 11 | Cross support for wooden floors |

| 12 | Pallet cross support |

| 13 | Shims |

| 14 | Collision protection (U-shape) |

| 15 | Collision protection (L-shape) |

| 16 | Container support |

| 17 | Portal connection |

| 18 | Metal shelf |

| 19 | Barrel supports |

| 20 | Wall connectors |

Sheet metal working

From sheet metal processing and welding to the powder-coated end product—everything from a single source! State-of-the-art machinery and 50 qualified employees are available for production and powder coating in a 2,000 m² hall.

| Sheet metal blanks | Sheet metal formats | 4.100 x 2.000 x 15 mm |

| Automatic punching machine | Steel strip | 200 mm x 4 mm |

| Folding bench | Bent parts | 4.100 mm length |

| Band saw with roller conveyor | Profiles, pipes | 12.000 mm length |

| Row drilling machine (8 heads) | Profiles, pipes | 6.000 mm length |

In addition, we have several presses with a pressing force of 1,500 kN. The welding shop includes its own tool shop and 8 manual welding stations. The connection between powder coating and sheet metal processing provides our customers with significant logistical, organizational, and economic advantages.

Powder coating

Several Polish and German companies collaborated to develop an automatic powder coating system that meets all European Union environmental and safety standards.

Parts can be coated with the following parameters:

5.40 m (length) x 1.50 m (height) x 1.00 m (width), maximum weight 500 kg.

8 high-performance precision guns mounted on pneumatic manipulators ensure a uniform and ideal application of the powder coating. To flexibly meet customer requirements, we also have a manual application system that allows powder coating of complex components by hand. Thanks to a quick color-change system, we are able to process all powder types of the RAL color system.

State-of-the-art powder recovery and exhaust filtration systems ensure environmentally friendly and material-efficient coating.

At optimal capacity, we coat up to 2,500 m² per day in three-shift operation.

Facade Construction

In addition to manufacturing components for storage technology and accessory parts for pallets and industrial racks, MAGNiflex has also established itself in the field of steel construction and industrial facade construction. The focus is on producing load-bearing and cladding facade components made of steel and sheet metal, used in modern industrial, logistics, and storage buildings.

We manufacture precise facade elements, substructures, brackets, and wall brackets for facade construction as well as connection and cover profiles for a wide range of applications. Thanks to our extensive expertise in sheet metal processing, welding technology, and powder coating, we produce durable, weather-resistant, and aesthetically high-quality steel structures for facades.

The close integration of design, production, and coating enables us to deliver facade elements exactly according to customer specifications and in optimal quality. Whether individual parts or complete assemblies – MAGNiflex stands for precise execution, short delivery times, and solutions that convince both technically and economically.

Clearly structured processes for quality and efficiency!

From the first idea to delivery, every product at MAGNiflex is created in precisely coordinated steps – all from a single source.

1. Inquiry & Consultation

Together with our customers, we define technical requirements, quantities, and deadlines. Upon request, a personal consultation can take place directly on site to coordinate all details precisely.

2. Design & Planning

Based on drawings or CAD data, we develop optimal solutions for production. Material selection, design, and manufacturing processes are efficiently aligned.

3. Production

With state-of-the-art machinery, precise components and assemblies made of steel and sheet metal are produced – from cutting and welding to mechanical finishing.

4. Powder Coating & Surface Treatment

Our integrated powder coating system ensures durable, resilient surfaces in all RAL colors – environmentally friendly, cost-effective, and technically at the highest level.

5. Quality Assurance

Continuous inspections throughout the entire process ensure dimensional accuracy, stability, and consistently high product quality.

6. Packaging & Delivery

Project-specific packaging, flexible logistics, and Europe-wide delivery ensure on-time shipping and safe arrival of the finished products.

Customer satisfaction is MAGNiflex’s top priority.

In addition to precise manufacturing, we offer our partners comprehensive services –

from the initial inquiry to long after delivery.

Consulting

Every project begins with individual consultation. Our experienced team supports you with technical design, material selection, and product optimization to find the right solution for every requirement.

Maintenance & Spare Parts

For all components and assemblies we manufacture, we supply suitable spare parts when needed or perform maintenance work. This ensures the long-term functionality and reliability of our products.

Customer Support

Our customers benefit from direct communication, short decision-making processes, and reliable follow-up support. Even after project completion, we remain available as your contact partner – fast, flexible, and solution-oriented.

Customer satisfaction is MAGNiflex's top priority.

Address

Magniflex KG

Beethovenstr. 58

89518 Heidenheim

Germany

Contakt

Phone: +49 7321 3493-0

Fax: +49 7321 3493-29

E-Mail: headquarters(at)magniflex.de

Web: www.magniflex.de